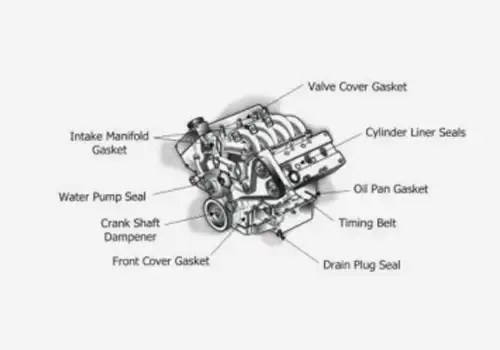

Engine parts & gaskets

HNBR 3310L

The vulcanization characteristics, mechanical strength and other indicators are similar to those of similar foreign products.

Keywords:

Category:

HNBR

Product Introduction

After more than a year of optimization and operation, Qilu HNBR plant has achieved continuous and stable production, and the product quality has been greatly improved, which is comparable to similar foreign products; the vulcanization characteristics, mechanical strength and other indexes are similar to those of similar foreign products.

Technical indicators

Sports event | Technical indicators | ||||||

Grades | HNBR3601 | HNBR3605 | HNBR3605D | HNBR3305L | HNBR3310L | HNBR3603 | Experimental Methods |

Raw Gum Menni Viscosity | 85±5 | 85±5 | 80±5 | 60±5 | 60±5 | 90±5 | The amount of sample according to GB/T15340-2008 over-roll method. |

Volatile matter (mass fraction)% | 0.6 | 0.6 | 0.6 | 0.6 | 0.6 | 0.6 | GB/T24131.1-2018 Oven method B |

Ash (mass fraction)% | 0.8 | 0.8 | 0.8 | 0.8 | 0.8 | 0.8 | GB/T4498.1-2013.Method A |

Hydrogenation | 99 | 95±2 | 95±2 | 95±2 | 91±2 | 95±2 | SH/T1762-2008 |

Acrylonitrile content(mass fraction)% | 33±3.5 | 33±3.5 | 36±3.5 | 33±3.5 | 33±3.5 | 35.5±3.5 | SH/T1157.2-2015, Method B |

HNBR Applications

Hydrogenated Nitrile Butadiene Rubber (HNBR) is now mainly used in the manufacture of seals, gaskets, 0-rings, hoses, transmission belts, molded products, rubber rollers, oilfield industrial products, wires and cables, and other products.

HNBR Rubber Compound is an advanced elastomer material known for its excellent resistance to heat, oil, and mechanical stress. This specialized compound offers outstanding durability, making it a preferred choice in industries such as automotive, oilfield, and industrial machinery. With superior strength and flexibility, HNBR Rubber Compound ensures reliable performance even under extreme working conditions.

One of the key advantages of HNBR Rubber Compound is its exceptional resistance to fuels, lubricants, and aggressive chemicals. Unlike standard rubber materials, this compound maintains stability when exposed to oils and high temperatures, significantly extending the service life of critical components. Its resilience makes it suitable for seals, gaskets, and O-rings that require long-lasting performance.

HNBR Rubber Compound also demonstrates excellent wear resistance, tensile strength, and compression set properties. These mechanical features allow manufacturers to design components that can withstand high loads, pressure fluctuations, and continuous operation. As a result, it is widely used in demanding engineering applications where reliability is essential.

Whether for automotive sealing systems, hydraulic applications, or industrial equipment, HNBR Rubber Compound delivers proven performance and cost efficiency. It is a material that combines strength, flexibility, and chemical resistance, making it one of the most trusted compounds for modern engineering challenges.

Contact Us

Address

Room 1211, Building 3, Guohao Financial Building, No. 380 Zhengyang Road, Chengyang District, Qingdao, Shandong Province, China

What Makes Us So Different From Other Suppliers?

Please contact us to provide you with satisfactory products and become a reliable supplier and service provider in the industry

Experiences

It is a comprehensive enterprise focusing on the production, sales, and import & export trade of rubber raw and auxiliary materials as well as polymer materials

Product Application

Which are widely used in various fields such as automobile and motorcycle parts, home appliance parts, and industrial seals

Marketing Network

Now it has already imported and exported with many countries including Japan, South Korea, the United States, Malaysia, Vietnam, Thailand, Russia etc

24-Hour Service

When you have any questions at any time, we will respond and act quickly, serving you 24/7 at any time

Factory Environment

We have independent production base where include advanced cnc machining center, fully-auto painting line, intelligent assembly line

Factory production professional equipment

In the factory, workers are producing various rubber mixtures

Plant Equipment

Plant Equipment

Plant Equipment

Plant Equipment

High and low temperature stress relaxation testing machine

High and low temperature flexural testing machine

Need Assistance? We're Here To Help!

Please contact us to provide you with satisfactory products and become a reliable supplier and service provider in the industry

Other Products

The company specializes in the production of zinc dimethacrylate (ZDMA/ZDA), maleic anhydride grafted polybutadiene, rubber additive LS-3, and trades Sinopec HNBR

Bisphenol AF and Fluoroelastomer 5# Vulcanizing Agent

Hydrogenated Nitrile Rubber Compound

Low cost rubber product additives adapted for conveyor belts